The Sisalation Shift

When Insulation and Wraps Changed the Rules.

In the early 20th century, homes were built differently, and for good reason.

Materials like hardwood weatherboards, breathable renders, and timber floors suspended above the earth allowed air and moisture to move freely. The homes were drafty by today’s standards, but they dried out. They lasted.

Then came the efficiency movement.

To reduce heat loss, builders introduced insulation.

To prevent wind-driven rain and drafts, they added reflective foil and synthetic wraps like sisalation. These were seen as improvements and they were. But they also marked a turning point in building science.

Because when you start wrapping and insulating a home that was never designed to be sealed you change everything.

What Is Sisalation, and Why Was It Introduced?

Sisalation is a brand name for reflective foil laminate a building wrap used in wall, roof, and floor assemblies to reduce radiant heat gain and resist water penetration. It replaced traditional breathable sarking (bituminous felt or paper), offering better resistance to rain, wind, and heat.

This was a big step forward in terms of thermal performance. But unlike older materials, sisalation and many modern wraps:

Are vapor-impermeable (they don’t allow moisture to pass through)

Reflect heat and stop air flow

Require carefully detailed joints and flashings to function properly

When builders started using these wraps without understanding vapor dynamics, things started going wrong.

Then Came Insulation

Around the same time, insulation became common bulk batts, loose fill, or rigid board in walls, ceilings, and floors.

Again, this was a major leap forward for thermal comfort and energy use.

But what wasn’t always considered:

Traditional homes relied on heat loss and air leakage to dry out wet materials

Adding insulation slows down drying and traps moisture behind linings

Improperly installed insulation can cause condensation inside wall cavities, especially in winter

The result?

Homes that were warmer and quieter but also wetter and more vulnerable, especially when paired with poor ventilation and impermeable cladding.

Vapour Management

The Forgotten Discipline

Water vapor is invisible. You can’t see it, but it’s always present — from cooking, showers, breathing, and climate. It moves by diffusion (through materials) and air transport (with airflow).

Once we started wrapping and insulating homes, we should have started asking:

Where does the vapor go?

How do we ensure it dries out again?

But too often, that question was never asked.

Instead, we ended up with:

Vapor barriers on both sides of walls (e.g., foil wrap outside, paint or tiles inside)

Timber frames absorbing moisture with no ventilation or drying path

Insulation packed tightly into moist areas like subfloors or south-facing walls

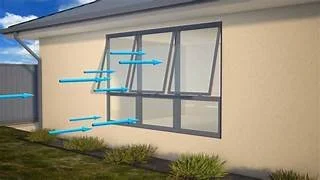

Homes with no mechanical ventilation, relying on opening windows for airflow (which doesn’t happen in winter)

An Unintended System Failure

By adding sisalation and insulation without changing how we think about drying and airflow, we created a new type of building envelope. It was tighter, more complex, and less forgiving.

What once relied on natural air movement to stay dry now needed:

Engineered ventilation

Correct vapor-permeable layers

Thorough flashing and detailing

Holistic design thinking — not just product swaps

When these elements weren’t integrated properly, homes became moldy, damp, and sick.

Leaky building syndrome isn’t always about bulk water intrusion — sometimes, it’s simply trapped vapor that never got out.

Renovating with Respect for the Building Envelope

If you’re renovating a heritage or older home, here’s the big takeaway:

You can’t just add new materials to an old home without rethinking how it breathes, dries, and stays healthy.

For example:

Adding insulation to a weatherboard wall without a vapor-permeable wrap can trap condensation

Lining an old brick chimney breast with foil-backed plasterboard can cause spalling and decay

Retrofitting foil insulation in the subfloor of a draughty cottage can create perfect conditions for mold

The key is not to avoid these upgrades. It’s to design them with building science in mind.

How Shepherd Homes Approaches This

At Shepherd Homes, we see every renovation as a balance between:

Preserving what works in an older home

Upgrading performance thoughtfully

Avoiding unintended consequences

We don’t just follow trends, we understand why materials behave the way they do. That means:

Choosing wraps and insulation to match wall design and climate

Considering how each assembly will manage moisture

Allowing older homes to dry the way they were meant to or updating them carefully when that changes

We build for comfort, health, and longevity not just code compliance.

The National Construction Code Is Not Enough

Unfortunately, the National Construction Code (NCC) doesn't fully protect against the risks we’ve described. It focuses on:

Fire safety

Structural integrity

Energy ratings

Basic water resistance

But it doesn’t require:

Vapor management strategies

Balanced ventilation design

Hygrothermal modelling (moisture behavior in assemblies)

That means even a compliant renovation can lead to premature decay, mold, and failure especially in older homes. This is why working with a builder who understands what lies beyond the code is so essential.